Get your skate sharpening machines ready for the season!

It's time to get those skate sharpening machines up and running, ready for the upcoming sharpening season!

Blademaster technical support is here to assist if you have questions!

Large Blademaster Skate Sharpening Machines

- Wait a few minutes before powering on heads. The computers need a bit of time to power up. (For variable speed machines, wait 1 minute after bringing power to the machine before attempting to turn on finishing head(s). The variable speed drive requires time to boot up and if you try to turn the head on too soon after power on, the drive will lock out and you will need to turn power off to the machine completely, wait 60 seconds, turn machine back on again and wait 60 seconds before turning the finishing head on again.)

- Check your switches. Switches are the most common point of failure on a machine. If you’re having any issue with the exhaust or wheel not turning on, check all connections on the switch to confirm they are securely attached. It is recommended to keep spare switches on hand so that you can also swap out old switches with new to determine if the switch is the issue or if there’s something else causing the equipment not to work. On applicable machines, check fuse holders for indication of blown fuses and replace as needed. Much like switches, it is recommended to have spare fuses on hand to limit downtime.

- Clean filter and empty grit tray – DO NOT USE WATER! Use an air blower from the inside out. Make sure filter is in properly and tight. Filter should not rotate without adequate force being applied to it.

- Slide feed system in and out by hand and check for any sticking points. If there is any sticking/crabbing that occurs when sliding the yokes in and out by hand then this is a sign that the linear bearings need to be replaced.

- Feed the screw assembly as far in and out as possible and make note of any sticking/jumping that occurs. This may be a sign of the linear bearings needing to be replaced or it may be in the Feed Screw Assembly. Slide the yokes in and out by hand and see if any sticking/jumping occurs, if not then the issue is likely the Feed Screw Assembly. This may be fixed by cleaning out the threads in the Feed Screw or the Feed Tube but may need overall replacement if issue continues despite threads being cleaned.

Join Dani B in the Blademaster Skate Lab as she walks through big machine maintenance!

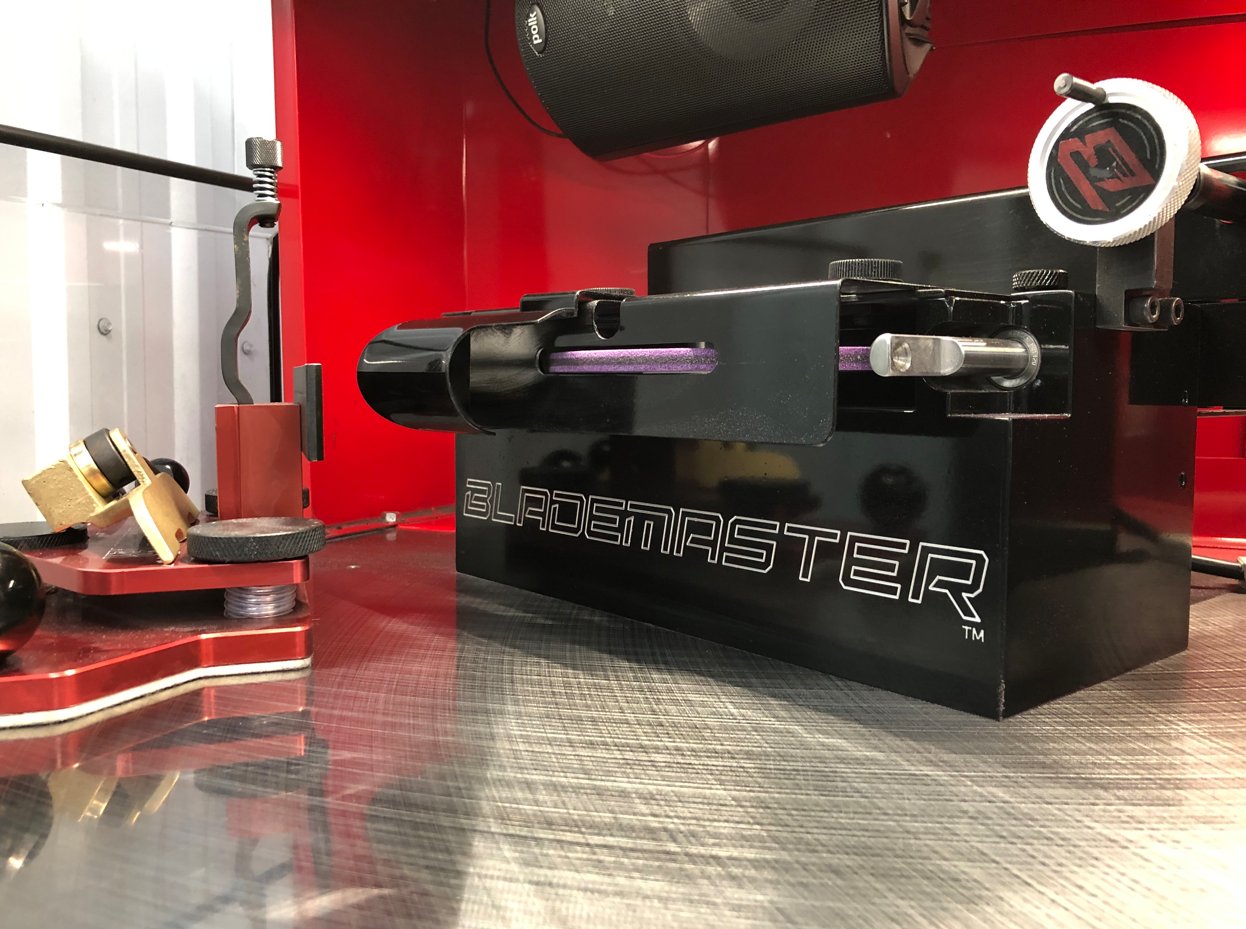

Blademaster Portables

Checks are relatively the same on portables vs big machines - except for the exhaust.

**Make sure that the portable is on a steady surface to absorb vibration of the motor and prevent it from getting transferred onto the blade when sharpening.**

- Check power supply – check outlet for power.

- Check switch – check connections.

- Make sure dressing arms are free from grit debris buildup. (do not use compressed air)

- Check center height adjustment – adjust if needed